Soil Vapor Extraction and Thermal Remediation with Lightweight Cellular Concrete

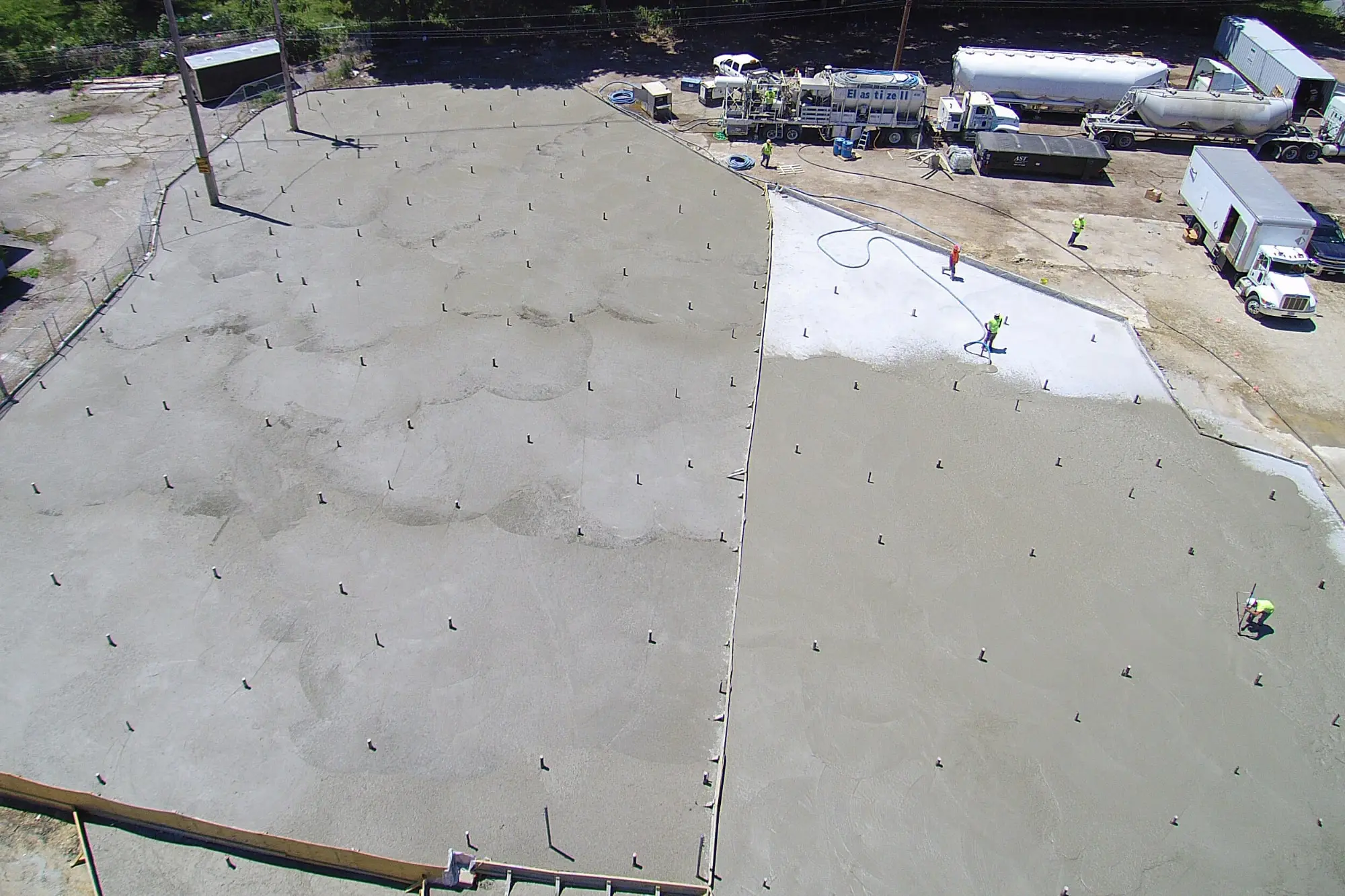

Lightweight Cellular Concrete (LCC) by Elastizell Systems provides a highly effective, durable solution for environmental protection and soil remediation. Its unique properties make it an ideal material for use in Soil Vapor Extraction (SVE) systems and as insulation for in-situ thermal remediation, enhancing efficiency and reducing the environmental impact of these complex remediation projects.

Soil Vapor Extraction (SVE) Solutions with Lightweight Cellular Concrete

Soil Vapor Extraction (SVE) is a widely used technique for removing volatile organic compounds (VOCs) and other contaminants from the soil. In SVE systems, Lightweight Cellular Concrete serves as an effective sealing material around extraction pipes, creating a stable, lightweight, and durable barrier that supports vapor extraction. This secure seal helps maintain the vacuum applied to the soil, improving the efficiency of contaminant removal and preventing the escape of harmful vapors. LCC’s superior strength and stability also prevent settlement and cracking around the pipes, ensuring the integrity of the system throughout the remediation process.

Insulation for In-Situ Thermal Remediation

In addition to its use in SVE systems, Lightweight Cellular Concrete is a preferred material for thermal remediation applications due to its excellent thermal resistance. During in-situ thermal remediation, high-energy electrodes are used to vaporize contaminants in the soil. LCC’s high R-value helps trap heat within the soil, making the remediation process more efficient by preventing heat loss. This reduces the overall energy required and ensures that VOCs are vaporized more effectively, allowing for easier extraction through SVE systems. The integration of LCC in these systems enhances their performance and supports the successful cleanup of contaminated sites.

Enhancing Efficiency in Soil Remediation Projects

In many contaminated sites, the removal and replacement of soil can be time-consuming and costly. With Lightweight Cellular Concrete, there is no need for extensive excavation. Instead, LCC can be used to support and enhance SVE and thermal remediation efforts, stabilizing the soil in place and preventing further spread of contamination. This is particularly beneficial for Superfund sites and other high-priority remediation projects where environmental disruption needs to be minimized.

Cost-Effective Remediation

Lightweight Cellular Concrete offers a cost-effective solution for soil vapor extraction and thermal remediation due to its lightweight nature and ease of installation. Compared to traditional materials, LCC requires less material to cover large areas while providing superior thermal insulation and structural stability. This reduces the overall cost of remediation while still ensuring long-term containment and efficiency.

Long-Term Durability and Stability

Lightweight Cellular Concrete provides a long-lasting, stable layer that supports SVE systems and in-situ thermal remediation processes. Unlike traditional materials that may shift, settle, or degrade over time, LCC remains structurally sound, maintaining its integrity and preventing the migration of contaminants. This durability ensures that SVE systems and thermal remediation efforts remain effective for decades, making LCC an excellent choice for both short-term and long-term environmental protection.

Minimal Environmental Impact

The lightweight nature of Lightweight Cellular Concrete minimizes the stress on underlying soils, reducing the likelihood of settlement or soil shifting. This is particularly important in areas where the soil is already weak or contaminated. The use of LCC helps preserve the natural environment while containing harmful materials, making it an environmentally friendly solution for complex soil remediation projects.

Versatile Applications for SVE and Thermal Remediation

Lightweight Cellular Concrete is ideal for use in high-priority remediation projects, such as Superfund sites, where soil contamination requires advanced techniques like SVE and in-situ thermal remediation. By integrating LCC into these systems, the remediation process is enhanced, and contaminants are managed more effectively with minimal disruption to the surrounding environment.

The Advantages of Lightweight Cellular Concrete for SVE and Thermal Remediation

- High R-Value for Insulation: Lightweight Cellular Concrete’s excellent thermal resistance helps retain heat within contaminated soils, making in-situ thermal remediation more energy-efficient and effective.

- Enhanced SVE Efficiency: LCC forms a tight, durable seal around extraction pipes, improving the efficiency of Soil Vapor Extraction systems by minimizing air leakage and maintaining vacuum pressure.

- Long-Term Durability: Lightweight Cellular Concrete creates a stable, durable barrier that resists settling and shifting, ensuring that the system remains intact for decades.

- Minimal Disruption: Using Lightweight Cellular Concrete in SVE and thermal remediation reduces the need for excavation and extensive soil movement, minimizing environmental impact while maintaining the integrity of the remediation project.

- Cost-Effective Solution: Due to its lightweight properties and ease of installation, LCC offers a more cost-effective approach to soil remediation than traditional materials.

Why Choose Elastizell Systems for Soil Vapor Extraction (SVE) and Thermal Remediation?

With over 65 years of experience, Elastizell Systems is a trusted leader in providing Lightweight Cellular Concrete solutions for complex environmental remediation projects. Our innovative use of Lightweight Cellular Concrete (LCC) enhances the efficiency and effectiveness of Soil Vapor Extraction (SVE) systems and in-situ thermal remediation. We offer custom mix designs tailored to each project’s unique requirements, ensuring a secure seal around extraction pipes and superior thermal insulation properties.

Whether you’re managing a Superfund site or a high-priority remediation project, our on-site mixing and precise application techniques ensure minimal disruption, reduced costs, and long-term stability. Elastizell Systems is your reliable partner for achieving optimal remediation outcomes with innovative, sustainable solutions.

Contact Elastizell Systems today to discover how our Lightweight Cellular Concrete can enhance the stability, safety, and longevity of your Soil Vapor Extraction (SVE) and Thermal Remediation projects.

Expertise You Can Trust

Decades of experience in providing innovative remediation solutions using Lightweight Cellular Concrete (LCC) for Soil Vapor Extraction (SVE) and thermal remediation projects.

Tailored LCC Solutions

Custom LCC mixes are designed to enhance SVE efficiency and provide superior thermal insulation, ensuring effective contaminant removal and long-term stability.

Environmental Engineering Excellence

Our environmental engineers leverage their expertise to deliver precise and durable solutions for complex remediation projects.

Seamless Project Management

From planning to completion, we manage SVE and thermal remediation projects with precision, ensuring timely delivery and adherence to budget.

Durable, High-Quality Products

We use top-quality Lightweight Cellular Concrete to support long-lasting and effective remediation efforts, providing reliable containment and insulation.

Versatile Applications

Adaptable LCC solutions for Soil Vapor Extraction (SVE), in-situ thermal remediation, and complex environmental projects across diverse site conditions.